In Metal I studio, I learned how to manipulate tin and aluminum in the form of sheet metal, using various hand tools and machinery.

Tin

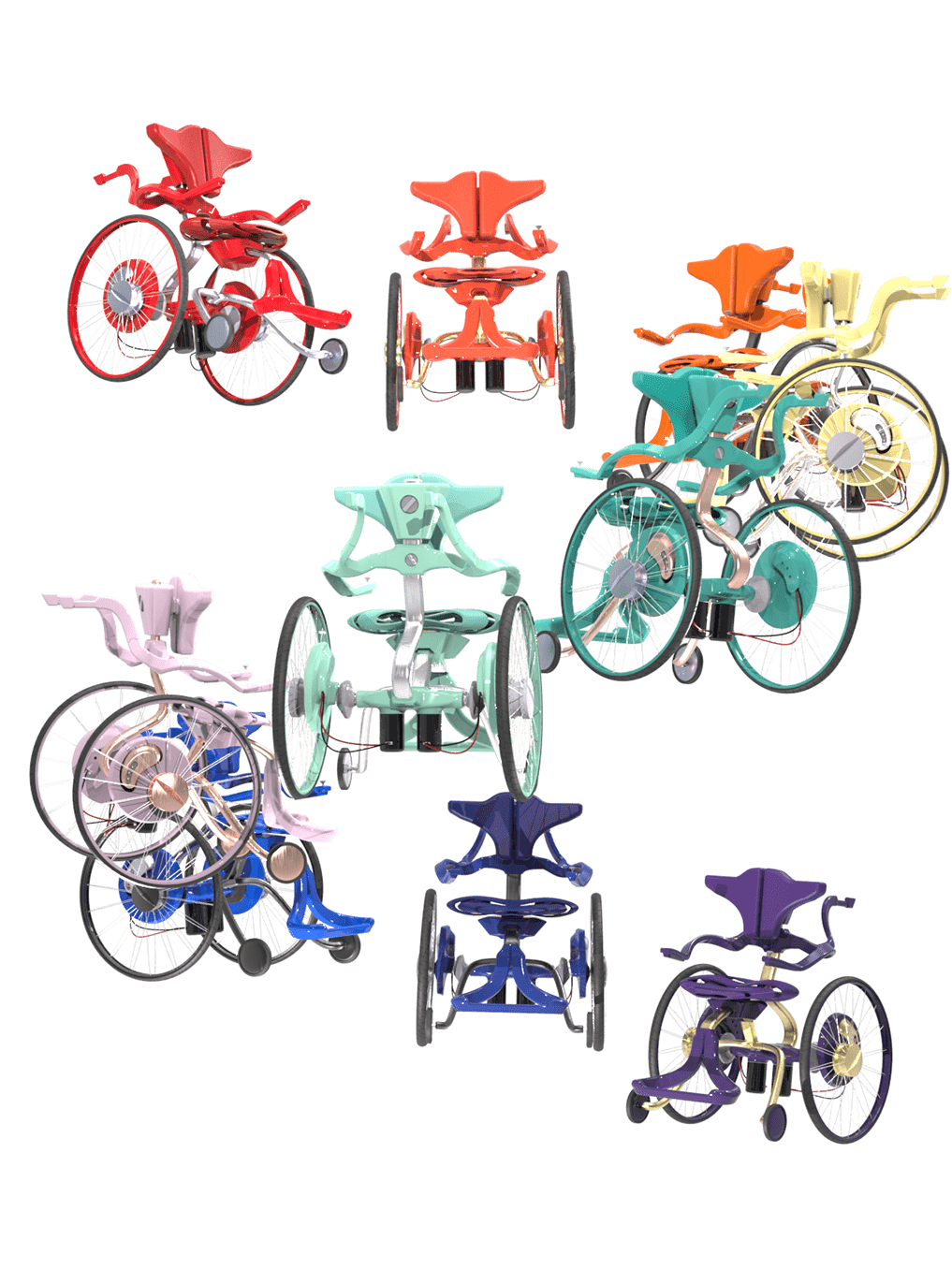

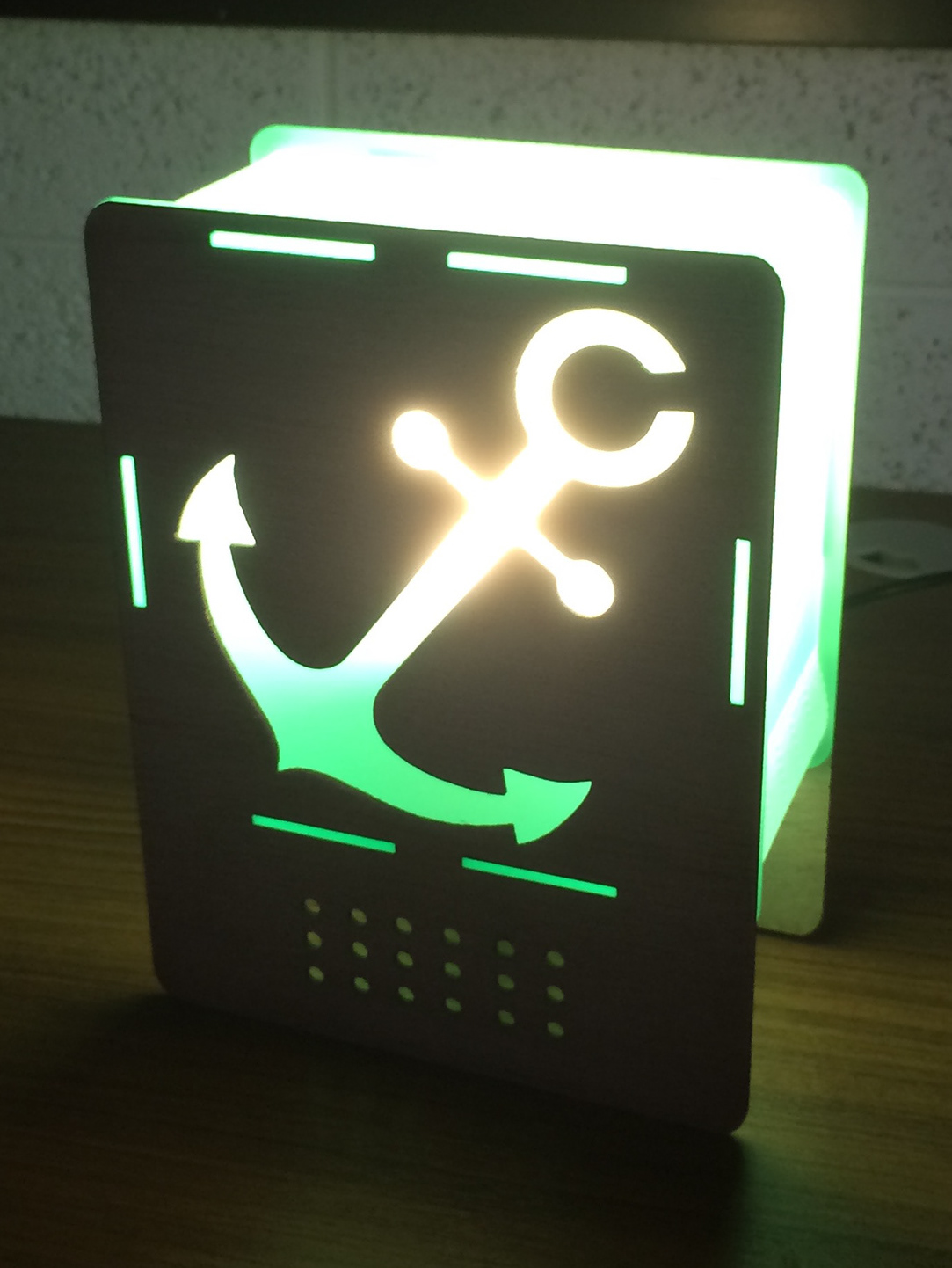

This modular piece was made using the finger break. The edge of each 'c' shape was folded so they could clip onto each other to make different forms.

This form was made using the hydraulic press. Using the characteristic of tin as a very malleable metal, I pressed the tin sheet in the hydraulic press along with an 'o' shaped rig to achieve the concave shape. Then two concaves were put together to create the bulbous volume. The copper rods and the hinges allowed for the modules to move around.

Aluminum

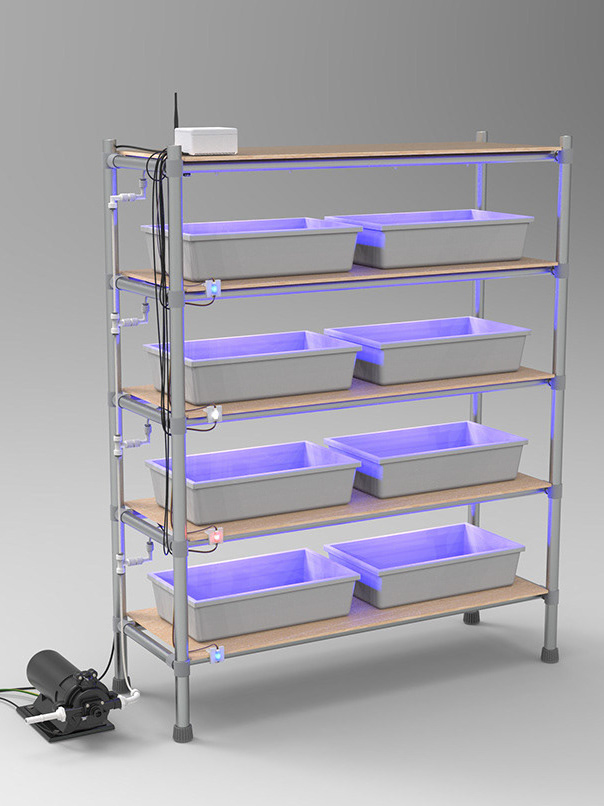

I explored a lot with tension-fitting when I was studying aluminum due to its more rigid characteristic. The piece above is held together with 5 separate pieces pressing on each other with no physical attachment. The piece below is held together by 3 separate pieces.

The spiral piece is structured by 6 's'-shaped aluminum parts applying pressure inwards whereas the ring in the middle pushes the 's' pieces outwards.

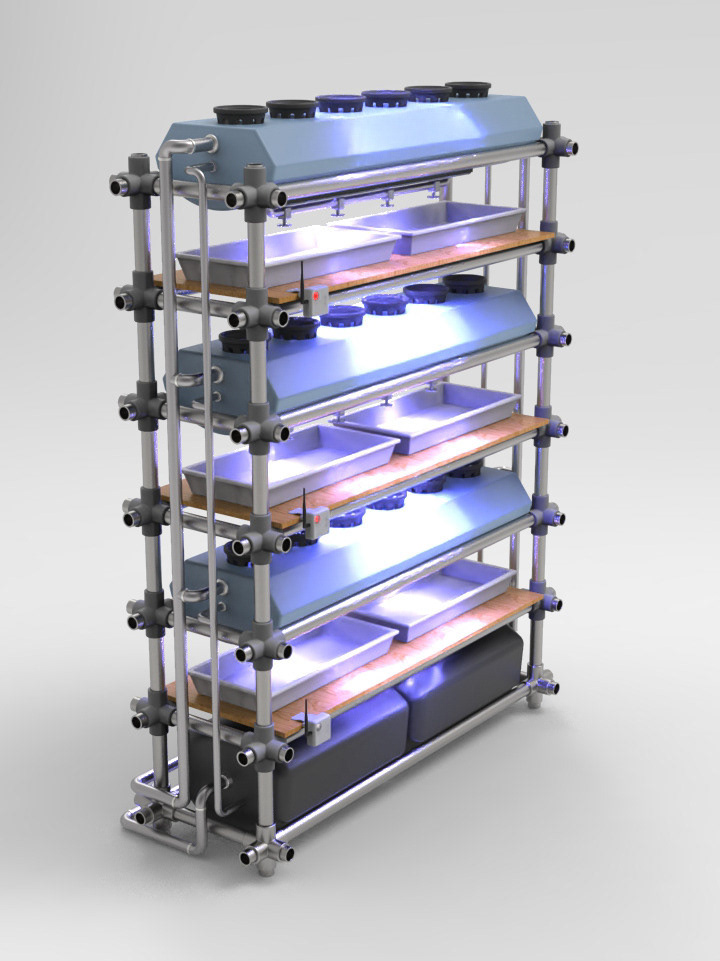

This hexagonal structure was created by tension-fitting nine pieces. If any of the nine pieces are taken out, the structure collapses.